A rectangle sharpening stone and a circular sharpening stone are the two forms of combination sharpening stones.

Rectangular Combination Sharpening Stone

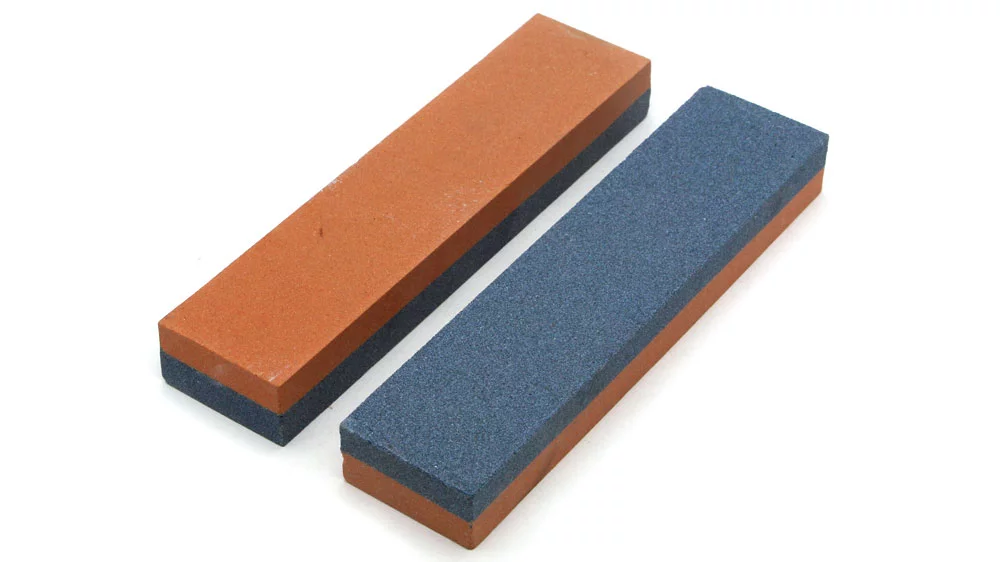

Bench stone is the name given to a rectangular combination sharpening stone. It’s a flat stone that’s great for sharpening straight-edged tools like plane blades, chisels, drawknives, wood lathe cutters, precision tools, knives, spokeshaves, and fine instruments

Round Combination Sharpening Stone

Deburring, sharpening, and honing knives and other instruments are all possible with the Round Combination Sharpening Stone. It’s a sharpening stone manufactured of Crystolon, a silicon carbide abrasive that cuts quickly. It also comes in two distinct surfaces: a coarse 120 grit surface and a fine 320 grit surface.

Features of Aluminum Oxide and Silicon Carbide Vitrified Combination Sharpening Stones:

- This product is very user-friendly.

- It’s ideal for sharpening instruments regularly.

- Restore cutting edge on straight-edged instruments.

- Assists in maintaining the instruments’ slicing speed and general usefulness.

- Incorporate two distinct kinds of stones into a single piece.

Overview of Aluminum Oxide and Silicon Carbide Vitrified Combination Sharpening Stones:

Almost every competent cook understands how deadly a dull knife can be, much more so than one that is sharp. This is one of the key reasons why, to preserve high-quality slicing ability and overall utility, it’s a good idea to sharpen knives regularly. When it comes to sharpening knives, there are a variety of amazing instruments that may be used. The rectangular combination sharpening stone, which is generally available in aluminum oxide (India stones) and silicon carbide, is one of these well-known sharpening instruments (Crystolon stones).

Detail Description

A flat stone used for sharpening tools on a bench is known as a combination sharpening stone (bench stone). It’s a hybrid sharpening stone with two distinct grits on two separate faces: one for repairing steel cutting edges and the other for honing and maintaining them. These two sides might be constructed of the same material or separate materials with varying granularities. They’re constructed of silicon carbide and aluminum oxide, and they’re used to sharpen knives, glassware, and other such items.

A combination sharpening stone is great for creating cutting edges that are both robust and smooth. Knives, chisels, plane blades, and hand scrapers may all benefit from using them to sharpen and polish their edges. Sharpening may be accomplished in two separate methods. The first involves shaping or reshaping a cutting edge by grinding away portions of the metal to modify the angle of the edge and restoring the shape. The second procedure is honing, which entails eradicating minor flaws.

Common Uses:

- When compared to Waterstones, a combination sharpening stone is an oilstone that is known for its durability and moderate wear.

- It also retains flatness longer. It’s often utilized for a variety of purposes. These are some of them:

- To alter the angle of the edge and reconstruct the shape by grinding away sections of the metal.

- Getting rid of any minor flaws in the workpiece

Specification:

Below are the various specs of rectangular combination sharpening stone, featuring the grade, shape, and grit sizes:

| Type | Grade | Shape | Grit sizes |

| Combination Grit Sharpening Stone | Coarse | Rectangle | 80-100 |

| Combination Grit Sharpening Stone | Medium | Rectangle | 150-220 |

| Combination Grit Sharpening Stone | Fine | Rectangle | 280-320 |

Summary

For novices, combination sharpening stones are highly suggested. Users may choose from two distinct sorts of stone while using this type of stone. Sharpening and maintaining kitchen knives and other ordinary steel tools such as plane blades, chisels, wood lathe cutters, precision tools, spokeshaves, and sensitive instruments is easy with its silicon carbide and aluminum oxide combination sharpening stone.

Investing in a combination sharpening stone has various advantages. Aside from being very user-friendly, it’s great for regular knife sharpening. To top it off, you can use this sharpening stone to instantly restore the cutting edge on straight-edged equipment, ensuring fast slicing and general usage.

More customized Sharpening Stones are available, contact us.

[contact-form-7 id=”6642″ title=”Contact us”]